Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔧 Elevate your wiring game with Japan’s precision crimping powerhouse!

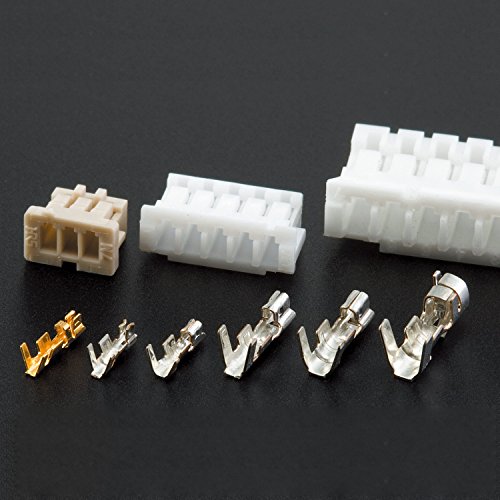

The ENGINEER PA-09 is a precision universal crimping tool made in Japan, designed for professional-quality crimps on a wide range of micro and mini crimp pins. Featuring a durable high-carbon steel body and comfortable thermoplastic rubber grips, it delivers reliable, ergonomic performance without the premium price of vendor-specific tools. Lightweight and compact, it’s the go-to choice for pros seeking flawless crimps on JST, Dupont, and other terminal pins.

| ASIN | B002AVVO7K |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 38,262 in DIY & Tools ( See Top 100 in DIY & Tools ) 117 in Crimpers |

| Certification | CE |

| Colour | Red |

| Customer Reviews | 4.6 4.6 out of 5 stars (2,374) |

| Date First Available | 7 Feb. 2012 |

| Handle material | Thermoplastic Elastomer (TPE) |

| Included Components | ENGINEER PA-09 crimping tool |

| Item Package Quantity | 1 |

| Item Weight | 135 g |

| Item model number | PA-09 |

| Manufacturer | ENGINEER |

| Material | Body: High carbon steel (S55C); Grip: Elastomer |

| Measurement System | metric |

| Part Number | PA-09 |

| Pattern | Single Item |

| Power Source | No |

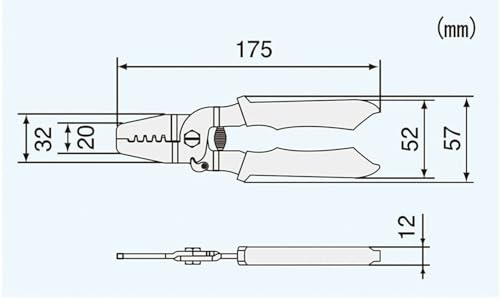

| Product Dimensions | 17.5 x 5.7 x 0.25 cm; 135 g |

| Style | Single |

| Usage | Pro |

M**S

A simple set of crimpers, that work extremely well.

Another excellent quality tool from the Japanese 'Engineer' company. These are a pair of manual crimpers for individual connection pins, such as Jst or Dupont pins. They are spring opening, with a catch to keep them closed when not in use. They come on a blister card, which has some helpful instructions and sizes on the back. (Photo). There is nothing fancy about them. There is no ratchet mechanism, no holding mechanism. All you get are a pair of manual grip crimpers. (Photo). Fortunately, none of that is really necessary and these work extremely well. In fact they are the best I've used. You place the pin in the relevant sized hole and squeeze. You do the conductor first, then move the pin to crimp the insulation. It works extremely well. Just make sure you use the right size hole. It can be fiddly, so it's a massive advantage if your pins are still attached to their manufacturing strip. You can still crimp the pins if they are individually loose, but it is a lot more fiddly. 'Engineer' do 3 different sizes of these crimpers. I personally think that these, the PA-20, are the most useful. I have never had to use a size bigger than 2.3mm or smaller than 1.6mm in all my years, so, I can't imagine needing a different pair. Your circumstances may be different, but if you are crimping standard 2.54mm pitch pins, these are the ones you want. Overall, these are a great set of crimpers, that work really well. Yes, they are a little expensive, but with nothing to go wrong, there is no reason why these shouldn't last a life time. Recommended. I hope you found this review helpful.

A**E

Well made, but not without problems.

I have been using this now for a couple of cheers to crimp JST pins onto ribbon cables, I love the JST connectors but I really do not like crimping them. There's a definite "knack" to using this tool, and even having crimped thousands of these, I still find them very fiddly to crimp. The JST crimps have 2 tab sections, one is used to crimp to the insulator ensuring that the cable is held in place, and the second is the actual terminal itself. The method that works for me is: 1.) bend the insulator tabs inwards very slightly with needle nosed pliers, if you don't do this, you won't be cable to perform the actual crimp. 2) place the crimp into this tool, I rotate the tool in my hand so the legend is facing away, I need to do this is ensure that I'm only crimping the insulator and not the other tabs, I gently close the tool slightly to grab the crimp, then rotate the tool back so the legend is visible, the back of the connector is now facing me. 3.) As I'm looking at the rear of the crimp, I insert t he cable into the crimp and look at the other side to make sure that I haven't pushed the cable in too far or not enough, it should be positioned so that the cable insulator is touching the outer tab, and the conductor is touching the inner tabs. 4.) very carefully I close the tool to perform the crimp. At this point, you might get a good crimp, or, you might end up with the crimp rotating in the tool jaws, in which case you have to reset everything and try again, the final problem you may get is that the tabs just didn't fold properly, in which case you need to remove the crimp/cut it off/trim the cable and so on. If the crimp was OK, then you repeat the process again, and crimp the inner tabs, just make sure that you check that you are not crushing the end of the crimp, if you do the pin won't be usable. Other issues also include the crimp bending. It works reasonably well most of the time, but sometimes they can be infuriating, especially when the tabs don't fold properly. This is a common issue I've read with this tool, but this is one of the best tools for these crimps, so I kind of just live with these issues. Take your time, and inspect everything before you make the actual crimp. It's also well worth having a multimeter set to "beep" mode, after crimping you should check that the cable is ok, sometimes the cable may more and the conductor might make no or poor contact.

B**T

Way to go for JST etc

Crimps coming out amazing, its night and day compared to chep-ones. Well worth the money if you need quality crimps.

M**D

Does an nice job but...

I need a tool that can crimp both JST-XH and Dupont connectors. These aren't it but to be fair they don't list Dupont or equivalent so that's not a critique of tool but just for awareness if that's functionality that you need. For the JST-XH crimps they work well but need two operations for each crimp and are dependent on the operator applying the correct amount of pressure whereas a ratchet tool only needs one and will always turn out a well closed crimp. On the flip side of that though, because each crimp requires two operations the tool is more open than a comparable ratchet tool and so gives better visibility of the work and consequently fewer failures than a ratchet tool. You pays your money and makes your choice as the saying goes. If you need a slim and lightweight crimp tool for occasional use without consuming a lot of toolbox space or adding a lot of weight then these are good quality and would serve you well but for frequent use and/or Dupont connectors I've found the Preciva Dupont crimping tool will handle both JST-XH & Dupont connectors (as well as some others), has a ratchet mechanism (which I personally prefer), comes with a set of JST & Dupont headers, crimps & housings and came in about £5 cheaper than this tool. In summary: A well made tool that is slim, lightweight and comfortable to use but there are cheaper options available with more features for more frequent use.

S**S

Lite liten

J**N

Crimpadora en dos pasos. De calidad excelente, se ajusta a la mano perfectamente.

T**Y

This is exactly the tool I have been after. I haven't been able to find a tool to crimp a specific type of terminal I use regularly but this has worked a treat. Basic easy to use tool allowing for perfect crimps.

E**L

Fait un travail précis et de qualité pour le sertissage de cosses miniatures pour connecteurs JST et semblables. L'opération doit se faire en deux temps pour la partie conducteur et la partie gaine du fil, et la pince a l'épaisseur appropriée pour cela. J'utilisais jusqu'ici un modèle plus gros (pour cosses de connecteur type MOLEX KK), dont les mors ont deux sections différentes permettant le sertissage des deux parties en une seule opération, mais leur épaisseur est trop importante pour les cosses miniatures. Vue la simplicité du mécanisme de la pince, il ne devrait pas y avoir de problème de durabilité.

J**0

Best tool I ever had for JST crimping, including ZH size, which is tiny. Recommended.

Trustpilot

2 weeks ago

4 days ago