Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

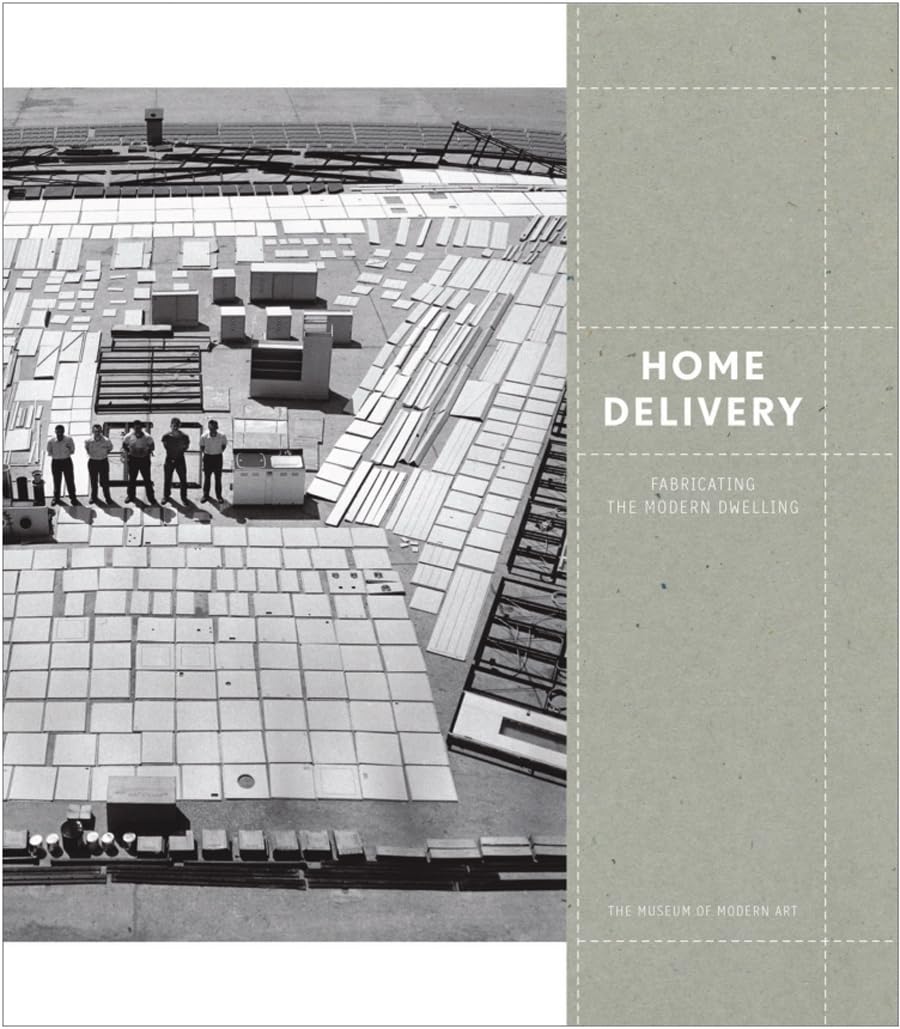

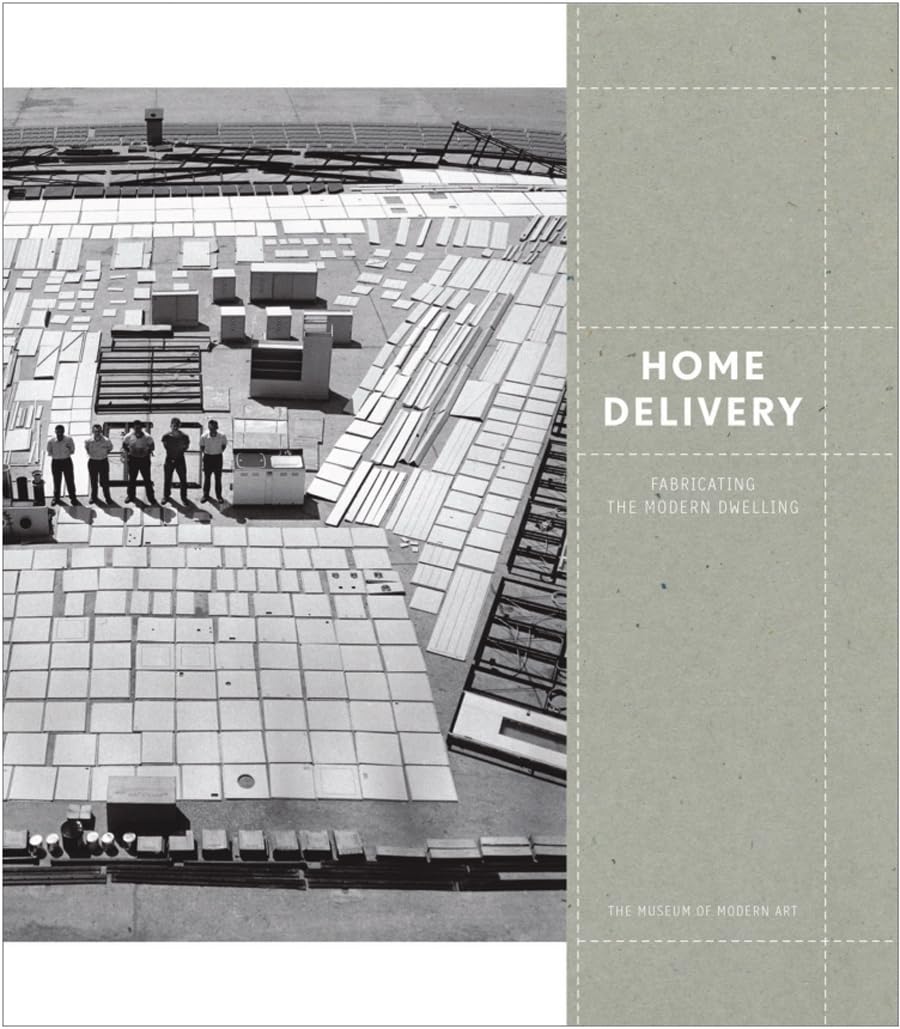

Home Delivery: Fabricating the Modern Dwelling

S**F

the MOMA has made history - and this book offers an excellent summary of that museum's contribution

I can't rate this book high enough and express with all due eloquence my admiration for the role the MOMA has played in the development of modern architecture. From the 1988 exhibition on deconstructivism to Home Delivery highlighting the wonders of prefab architecture, the MOMA has made history - and this book offers an excellent summary of that museum's contribution. It literally changed my views on prefab, opening up my horizon, freeing my mind and giving me new ideas for the design of my future house. It introduced me to luminary architects like Kieran Timberlake and their ethereal Cellophane house. I loved this book and regret somewhat having bought it second hand, though it arrived in reasonably good condition.

F**L

MoMA: "Home Delivery: Fabricating the Modern Dwelling"

Museum of Modern Art"Home Delivery: Fabricating the Modern Dwelling"Exhibition: 20 July - 20 October 2008, New York CityMonograph: "Home Delivery: Fabricating the Modern Dwelling"Authors: Barry Bergdoll and Peter ChristensenPublisher: Birkhäuser BaselISBN: 3764388625The Museum of Modern Art has created an excellent exhibition entitled "Home Delivery: Fabricating the Modern Dwelling". The exhibit and associated monograph spans from 1772 pre-fabricated colonies to today's cutting edge technologies as can be seen in the prototypes built by the KieranTimberlake Associates "Cellophane House", Horden Cherry Lee Architects / Haack + Höpfner Architects "Micro Compact" module, and Oskar Leo Kaufman + Albert Rüf, KFN Systems "System 3" projects.The beauty of this collection of works is to be able to look back over time, to see the mileposts of innovation over the years, ponder pathways that were cut short, and make connections between disparate projects to see a culmination of knowledge ripe for today's construction market.Within the exhibition, one can learn from a series of trends in the design and construction movement: Pre-Cut Parts, Panels, Frames, Modules, and Leveling Systems.Pre-Cut PartsThese individual pieces are shipped to a client for assembly into a more complex whole on site. The process employs mass production efficiencies and minimized shipping volumes. Sears & Roebuck Company's mail-order catalogue homes from 1908, with over 30,000 ready to assemble parts, epitomized this process. With the creation of nesting software that puzzles together two and/or three dimensional pieces within limited constraints, we are now able to maximize the amount of product cut from raw stock materials, and then pack these multiple elements into the most compact volume for shipping. Ikea has revitalized this process.PanelsIn the mid-1900's Walter Gropius spent a good deal of his career trying to rationalize the home into a mass-customizable system. Gropius, and his later partner Konrad Wachsmann, developed a panel system that cut a home into a series of pieces that could then be packed flatly on a truck's bed for transportation from a factory to the site. This method began to integrate multiple features into composite pieces for easier assembly. Today's Structurally Insulated Panels [SIPs], and the smart cartridges used by Kieran Timberlake Associates and others, pay homage to these roots. Zvi Hecker and Buckminster Fuller explored the potential of compiling non-orthogonal panels into more complex geometries.FramesBy pulling the structural paths out of the walls and floors into a defined matrix, frame systems open up the potential layout of spaces. In doing such, the structural frame is easily determinate for engineering, and it is possible to add additional space or reconfigure the walls, insert a window panel, etc. without having to recalculate the strength of the structure. This allows for a great flexibility over the life-cycle of a building, as a family might grow, change or have different needs.ModulesAs the cost associated with road transit lowered, it became feasible to assemble large numbers of piece off-site in an enclosed environment as modules. Use of this system allows a near turn-key solution to clients, since after initial site work is completed, a factory-built home may be trucked to the site, and craned into place with minimal effort. The wide-spread application of this construction methodology in manufactured housing has had difficulty in the public eye, which commonly relegates it to low-income trailer parks. Contemporary periodicals and museums have been doing much to redirect the stigma and bolster this type of off-site construction, so we will hopefully see continued innovation and optimism in this direction. The primary detriment of this system is the shipment of empty volumes [air], which soaring fuel costs will potentially eliminate as an option, unless intelligent design and nesting optimize the shipping volumes. Specialty areas, such as bathrooms or other `service' modules, with complex integrated systems are most appropriate for the additional inherent cost per cubic footage.The viable option of harnessing the potential of intermodal freight cargo containers, which were expressly designed for such applications, and can themselves be the structural frame for everything from single-family homes to seven-story mixed-use towers [i.e., Wes Jones' PRO/con housing, and Container City], was barely touched in this MoMA production.Leveling SystemsThe way in which a space engages the Earth has been a quintessential dilemma for architects of all time. le Corbusier called for a use of `piloti' in 1929, as a way to span uneven ground with ease, minimize surface impact for stormwater infiltration, create sheltered recreational space, and vehicular circulation. There are a number of projects that explore different ground plane leveling systems in this exhibit, but it is an area that still needs much research and exploration so that building sections may further engage plan and elevation based designs.Both the exhibition and the monograph are exceptional, and well worth in-depth exploration. I highly recommend it for professionals, students and patrons equally.Fredrick H. Zal, NCARB is an architect, sculptor and advocate for the fine + applied arts in Portland, Oregon. His architectural practice employs hybrid pre-fabrication techniques in commercial, institutional, single and multi-family mixed-use projects. [...]

Trustpilot

1 month ago

2 weeks ago