⚡ Align Like a Pro, Cut Like a Boss

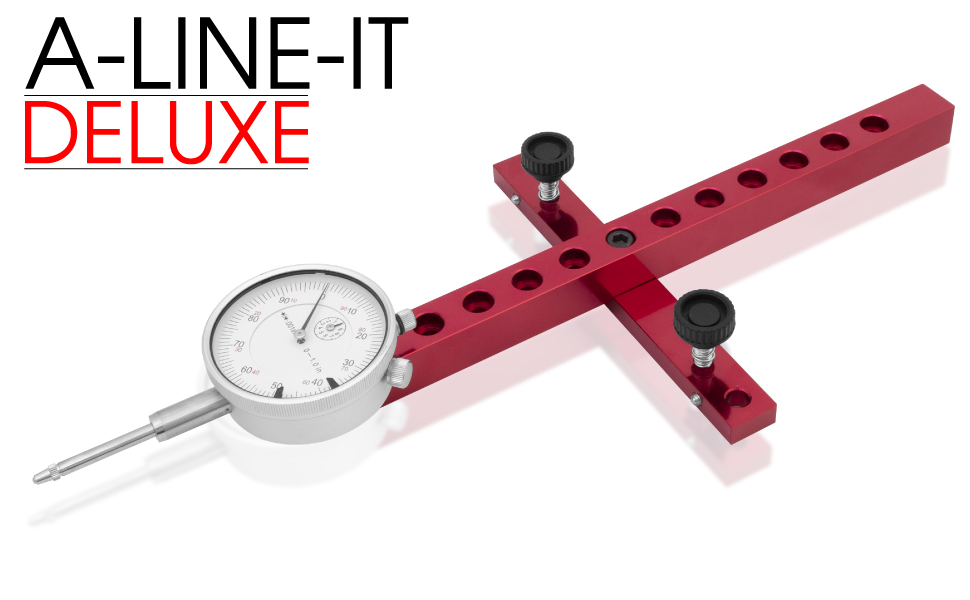

The A-Line-It Deluxe is a precision digital dial indicator alignment system designed for table saws and other workshop machinery. Featuring a self-adjusting Smart Bar and a comprehensive set of interchangeable tips, it measures blade, arbor, and fence run-out with .001” accuracy. This versatile tool kit helps professionals diagnose and correct misalignments across multiple machines, ensuring optimal performance and longevity.

| Manufacturer | In-Line Industries |

| Part Number | 3158 |

| Item Weight | 2.14 pounds |

| Product Dimensions | 9.7 x 8.3 x 2.9 inches |

| Item model number | 3158 |

| Is Discontinued By Manufacturer | No |

| Size | A-Line-It Deluxe |

| Item Package Quantity | 1 |

| Certification | certified frustration-free |

| Included Components | A-Line-It Deluxe System |

| Batteries Included? | No |

| Batteries Required? | No |

H**N

Works great, Simple setup

Works great, was able to align both the table and fence quickly. Make sure that you adjust the two screws to tighten the guide bar in the slot, if that's at all loose, then you'll get false readings

B**Z

Another step towards perfection

Before I bought my table saw, I thought it worked like this: you turn it on; you run a board through the blade; you turn it off.Then I bought a saw on craigslist (however it's spelled). It came with an Incra LS rip fence and router table. What the heck is that for?Soon, I was browsing back-issues of Shopnotes, reading about tenoning jigs, crosscut sleds and tapering jigs. So much to learn!And then one day, I read an article about tuning up your table saw. Huh? You could tune it? To what? A-440?Of course not. But the blade, I discovered, must be parallel to the miter slots, and the 90° stop position should align the blade exactly 90° to the table top. Was my saw in tune? I had to read up on banging something called a "trunion" with a hammer and a block of wood to parallel-ize the blade to the miter slot. Was my leg being pulled? Nope, that is the tried-and-true method.So, how to tell when I could stop beating on my saw? How will I know the blade is parallel to the miter slot? That's where the A-Line-It enters the shop. It rides in the miter slot and positions a dial gauge against the saw blade. Mark a spot on the blade, between the teeth, and rotate to the front of the saw. Put the stem of the dial gauge on the dot and zero the dial. Then rotate the blade towards the rear of the saw and move the A-Line-It so the stem of the dial gauge is again on the dot. If the reading is zero, congratulations! The beatings can stop! But if the dial does not read zero, well, it's back to the hammer for you.So, I banged and checked the front and rear positions. I banged and checked the front and rear positions again. I banged and checked the front and rear positions over and over, until they were as close to the zero as possible. I gingerly tightened the bolts holding the trunion and watched the dial. It changed slightly, and then went back to zero as I tightened one side and then the other.I slipped my new Incra miter gauge in the slot, laid down a block of 2 by 4, powered up the beast and ran the wood through the blade. Then I rotated one piece 180° and slid it up against the fresh cut. No gaps! No burn marks!I do not look forward to re-aligning my saw, using a hammer and block of wood. There is something called a P.A.L.S kit which supposedly makes the aligning process almost trivial, but I cannot speak to that yet.No matter what, the A-Line-It tool helped me put a song in my saw! The miter bars are machined aluminum, and vertically adjustable, so they should fit any depth of slot. Plus, there are spring-loaded bearings on the side of the miter bar to prevent slop. The included dial gauge is accurate to .001" (1/1000 of an inch!) which seem like way too much precision for my style of woodworking, but hey, if my saw is aligned to those tolerances, then everything I cut is better, right?Right! And for that reason alone, you should consider buying this tool. It isn't cheap, but you can save $20 if you have your own dial gauge.

M**N

There is some variability, so precision is certainly not to 1/1000ths of an inch

I ordered the $149 kit that allows one to check out saw blade alignment to miter groove, fence alignment to miter groove, drill press arbor as well as saw motor arbor run out. I had previously done this by feel and sight (using the miter groove, my miter, and a stick fixed to the miter).When I used the alignment it tool, my blade was off by 7/1000 inch. Since this analog micrometer gadget can show distances as small as 1/1000 " I was hoping to improve on the 7/1000 figure.I have a Sears Craftsman contractors saw, and an after market Vega pro fence. I use the PALS system to adjust the saw trundle, and was using a new ridge carbide blade to help align my saw blade. Even after tightening the trundle bolts and re-measuring distances, it was rare for me to get the same distance. I would say there was a 1/1000" variation when measuring the same distances. In addition, there are adjusting screws in the bar to ensure a tight fit in the miter groove. The screws can loosen between making several measurements, so you always have to check If there is any "slop" or play when the bar sits in the miter groove. Same process was repeated for measuring the distance from miter groove to fence. It did take many repeated measurements to convince myself that I was within 1/1000 " difference between the front and back of the fence. Part of the problem, I suspect is that I don't have an expensive cabinet saw, which may make adjusting the fence or sawblade more difficult: I'm just speculating, and maybe if I did try to use this tool with an expensive cabinet saw my experience would be a happier one.That being said, I'm still happy with this purchase and am now quite sure that my saw is in a better state than before. As to the tool itself, Jerry Cole has produced a very hi quality appearing tool. The tool came packaged in foam padding, with places for each of the parts. There were adequate instructions on how to use this as well as a DVD. I did not view the DVD. I might be tempted to purchase another analog digital micrometer gauge, but the one that came with this kit suits my needs for the time being.

Trustpilot

2 weeks ago

3 weeks ago