Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

🚪 Close the deal with Dynasty’s sleek, silent strength!

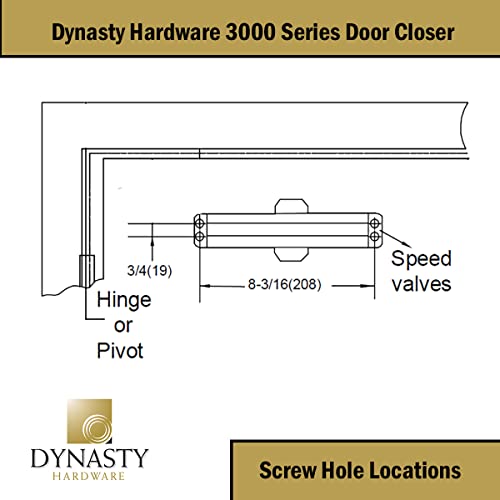

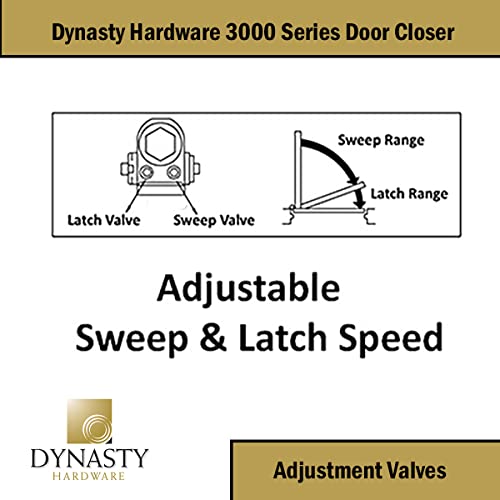

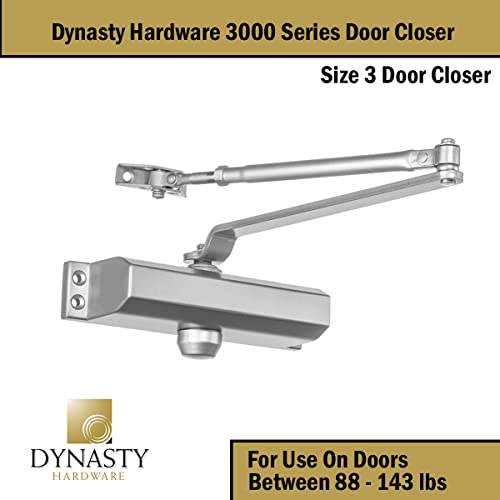

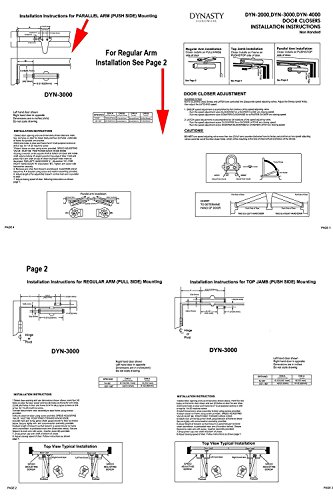

The Dynasty Hardware 3000-ALUM is a commercial-grade, size 3 hydraulic door closer featuring a compact aluminum alloy design with sprayed finish. It offers versatile mounting options and a non-handed mechanism that fits both right and left swing doors, ideal for interior and lightweight exterior doors up to 42" wide and 143 lbs. Perfect for hotels, apartments, and commercial spaces seeking reliable, space-efficient door control.

| ASIN | B01HP1OQE2 |

| Batteries Required? | No |

| Batteries included? | No |

| Best Sellers Rank | 722,169 in DIY & Tools ( See Top 100 in DIY & Tools ) 778 in Door Closers |

| Customer Reviews | 4.6 4.6 out of 5 stars (745) |

| Date First Available | 28 Jun. 2016 |

| Installation type | Screw-In |

| Item Package Quantity | 1 |

| Item Weight | 2.57 kg |

| Item model number | DYN-3000-ALUM |

| Item weight | 5.67 Pounds |

| Manufacturer | DYNASTY HARDWARE |

| Part Number | DYN-3000-ALUM |

| Pattern | Door Closer |

| Product Dimensions | 33.02 x 9.14 x 11.18 cm; 2.57 kg |

| Recommended uses for product | Gewerbegebäude |

| Size | 7.62 cm |

| Specification met | ANSI, UL |

| Style | Sprayed Aluminum |

| UPC | 636134553695 |

N**L

Working great

A**R

Good

R**D

In brief... 1> Great unit, works very well. I have a heavy outside-opening security screen door that needed a closer, this handles the job with ease. Obviously my metal screen door, while heavy-duty frame/screen has weight, is much lighter than a real metal door or solid wood door. But there's no way the light-duty $20 closers at the big box stores could handle this much mass, I'd go through them like chicklets. This thing is perfect for my door and needs. 2> There are three different ways to mount this closer, so I had to kind of sort through my options and decide which one would work best in my situation. Two of the options would have worked OK, but one proved to be simpler, when I held the closer up to the door where it would be mounted. You really have to be holding it in your hands, and hold it in place before you can be sure that all the screw holes on the door and door frame will line up OK. 3> It comes with a decent "template" for where the mount holes go, on the instruction papers. They worked great, just follow the directions - bend the paper here to expose an "edge" to match the door edge, then cut or fold as needed to situate the template right, and tape it into place (use good tape, there will be forces trying to dislodge it as you work). 4> Some reviews mention confusing instructions, and I have to admit - they seem to be written with general contractors in mind rather than average Joe citizen who does this once and never again. Really, it was holding the apparatus up against the door where the template showed it needed to go that suddenly clarified a lot of what I had read. You have to do both... read the instructions, and physically hold the equipment in place, then read again if something is unclear. Holding the things in place provides that "ah-HA!" moment that will let you proceed with confidence. 5> They offer some videos on their website that helped me - but each is for a different mounting technique. Pick the wrong one, and their video makes no sense. Pick the right one, and you'll have much more confidence that this is not really all that difficult. The right video helps a lot. 6> I had to go to Ace (a hardware store, any would do) to get the right screws for my specific door situation. I have a metal door, with a 1" hollow metal square tube as the mounting point. None of the provided screws would work, since those that were short enough were just bolts - not tapered or "self-tapping" - and the various screws that were included were too long - clearly intended for 2-2.5 inches of wood. Ace had what I needed, and I found out that a # 14 screw and a quarter-inch screw are the same cross sectional thickness. Well. You should learn something new every day, right? Four #14 x 3/4" screws later, I was all set. Just be aware - they can only anticipate the most common mounting arrangements and supply screws for those. My situation was NOT those, so... you might need special screws, as I did. 7> The closer itself, once mounted, works exactly as desired. The instructions about adjusting the speed of the door closing movement and the 2nd adjustment for the "last 10 degrees of travel" (slower but firm, to click the latch) all worked as expected, good instructions for that part. The included allen wrench for those two screws was all I needed, the adjustment took 3 minutes, maybe less. Very straightforward and easy (to me). To conclude, I found excellent value here. For half or less what others were priced at, I got a great door closer that installed fairly easily and handles the weight of this oversized metal screen door with no problem at all. The action is fairly stiff, as I wanted, and the last 10 degrees of "don't slam, but close firmly" works perfectly. I highly recommend this unit if you have similar needs for something larger than the little, flimsy closers that are everywhere for $20, but don't want to spend $80-150 on a commercial closer. Five stars, well deserved, highly recommended.

A**R

Excellent door closer.. as advertised

A**I

Works really well. I was surprised that it was easy to install. This saved me quite a bit of money by doing it myself.

Trustpilot

5 days ago

3 weeks ago