Customer Services

Copyright © 2025 Desertcart Holdings Limited

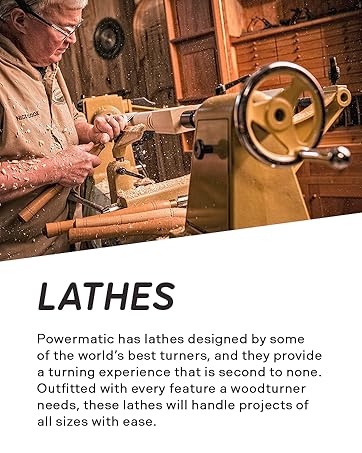

⚡ Turn your craft into a masterpiece with Powermatic precision!

The Powermatic 3520C is a heavy-duty, 2 HP woodworking lathe featuring a fully enclosed VFD, digital RPM and indexing readouts, and a variable speed range from 15 to 3200 RPM. Its ergonomic design includes adjustable riser blocks, a magnetic control box, and an upgraded banjo clamp, all built on a 726-pound cast iron frame for unmatched stability and precision. Ideal for professional woodturners seeking versatile, high-performance equipment backed by a 5-year warranty.

| Manufacturer | Powermatic |

| Part Number | 1353001 |

| Item Weight | 726 pounds |

| Product Dimensions | 69.5 x 36.5 x 47 inches |

| Item model number | 3520C |

| Is Discontinued By Manufacturer | No |

| Color | Yellow |

| Style | Lathe with Risers |

| Material | Cast Iron |

| Power Source | Corded Electric |

| Voltage | 220 Volts |

| Horsepower | 2 |

| Item Package Quantity | 1 |

| Measurement System | Metric |

| Included Components | Lathe, Centers (x4), Knockout Rod, 3" Faceplate, Tool Caddy (w/tools), Hardware, Riser Blocks (x2), Tool Support, Leg Assemblies (x2), Levelers (x4), 14" Tool Support |

| Batteries Included? | No |

| Batteries Required? | No |

| Warranty Description | 5 Year |

B**Y

Phenomenal

Rock solid construction, easy controls, and smooth operation! I had originally planned on purchasing the Jet 1840evs but opted for the Powermatic 3520c after months of research. I have ZERO regrets. Delivery was very professional and the lathe arrived in excellent condition.

J**S

It's HEAVY, so it doesn't move with out of balance blanks

This is a great professional quality wood lathe. I'm very pleased with the performance. You will need help to assemble it because it is heavy. The component parts are all heavy. I have forks on my tractor and they were a real godsend in getting the bed lifted up to attach the legs and risers. Mine did come with a loose power cord, but I needed to get a plug and outlet to complete the wiring. There are no instructions for that but it's not complicated if you have any experience in wiring. If you don't, get professional help. It costs too much to mess it up. I've turned several bowls of various sizes and a few spindle pieces. I'm very happy with it.

A**E

Love this lathe

I always wondered why this Powermatic lathe was priced so high. But after owning it I have yo say that it’s worth it. This is a beefy, well made machine. I love turning in it and feel I can turn just about anything on it too.

N**E

PM3520C

Wonderful machine. Arrived with everything boxed on one pallet in good shape.

S**R

Powermatic Wood Lathe

Just what I wanted. I turn bowls and other projects with the Powermatic. I have no issues with it, the packaging and delivery was excellent. Make sure you have assistance putting it together, it is heavy.

R**.

It comes with a power cord wire

Now there will be buyers or potential buyers of this product that will think the following criticism is pretty tricky tack. This $5,000 lathe does come with a cord/wire. It doesn’t have a plug on it which is understandable. What doesn’t make any sense is that it is NOT wired to the on/off switch on the machine. And in addition to not being wired to the machine, the power switch is not even shown on the 2 provided wiring diagrams. I am not an electrician and the “operators manual” clearly states that the lathe should be wired by one. But when you look at how the switch might be wired there aren’t many choices. There are 2 terminals and 2 wires, black and white, and both are carrying 110V. And the ground terminal is obvious and not on the switch. So why doesn’t Powermatic wire it? I can put the plug on. So I spent the better part of 2 days putting this 700# plus thing together and can’t plug it in and try it out. When you’re looking at the back side of the power switch, under that obviously very pricey VFD electronic motor controller, it is difficult to decide what wire goes to what terminal. Why doesn’t Powermatic wire the switch?? Most of us can wire a plug! Don’t bother calling customer support. All they do is cite the paragraph in the “operators manual”(notice NOT the installation manual) that says an electrician needs to wire it. And cite it over and over with every question of disbelief. So my question to you is do you really want to spent that kind of money and buy into a company that can’t address a problem this small? What happens when you have a real issue? It is too late for me. I’ve bought it. And I own other Jet and Powermatic tools. This is the last one I am buying. And believe me, I am looking at other tools. Next day update: My electrician buddy texted me back after looking at the pictures I sent. He said that both leads carry 110V and it doesn’t really matter which terminal. I matched the black cord lead to the black VDF lead and the white to the white(the terminals are numbered 1,2,3,&4 but I am not looking at the switch). I installed a 230V plug, plugged it in to an outlet and turned the power switch on. Next depressed the green on/off switch on the wired remote. Everything worked fine. Hoping that my next update will contain a few more stars.

S**H

Getting it assembled, unassisted, was an adventure

I live in the woods at the end of a gravel road. Thanks to Central Freight for good communication. I met the driver at a truck stop to receive the lathe and take it home on a car hauler.. I built a ramp and used a come-along winch to pull the components onto the bed of my Gator and into the shop. I could inch the lathe bed along the floor with a crow bar but couldn’t turn it over without bolting the winch to a wall joist and screwing boards at the bed edge so it would tilt and not slide. With the bed turned over I attached the legs, moved the winch up a bit, and successfully righted the assembly, again winching and screwing boards down to the floor to prevent sliding. I hung the winch on a chain looped over a ceiling joist to lift the headstock suspended by two ratchet straps. Adding the banjo and tailstock was anti-climactic. The tailstock quill unit was jammed, and I had to remove the crank wheel and force it with a major wrench. I don’t know why it was jammed, and it worked smoothly thereafter. The unit comes with an unattached power cord, and the manual is not helpful in how to attach it. A web search gave me the necessary info for final wiring including the addition of a 220 plug. I was thrilled to fire it up and enjoy the utterly quiet operation. I was too tired to mount and turn wood. I went to bed exhausted and sore but satisfied. Addendum: read my comments above about the quill jamming. It turned out that I was using a center with too short a Morse taper for the quill to eject. The quill screw was going beyond its threads and jamming. The second time I loosened the set screws on the wheel hub, the wheel hub was jammed. This was due to metal being raised by the set screws. I attempted to tap it off with a nylon hammer, and the cast spokes broke. I was unable to repair the wheel spokes by brazing, so I fashioned my own tail wheel out of brass with elegant wooden handles at my metal lathe. I certainly cannot fault the manufacturer and will not deduct a star for the Mustard Monster. And btw- the MM gently shakes my entire wooden shop floor with unbalanced wood-probably not noticeable if on concrete. I made myself finish a number of small projects prior to mounting any 20” log sections, and work is so much more stable and secure than with my midi even though manipulating the tailstock and tool rest are more ponderous.

K**G

It is a beast. Have help or a lift to assemble and install.

Powerful , heavy and smooth as silk. What greatly surprised me was how quiet it runs. Just be aware, you have to wire your own plug and it is a 220 v unit.

Trustpilot

2 weeks ago

4 days ago